Unfounded or not, the fear of climate change is driving the manufacturing sector to adopt green manufacturing and technology. Simply put, green manufacturing is the use of green technology; technologies that when used in any aspect of our lives, minimizes any impact on the environment.

Green technology is any technology that is environmentally friendly. Green manufacturing can be considered as the shifting of manufacturers from using traditional manufacturing processes to ones that reduce energy consumption. It also reduces emissions and pollutants, as well as the reduction of the use of natural resources through recycling. This also applies to new companies that use green technologies from the ground up.

Below are examples of green technology that apply to manufacturing.

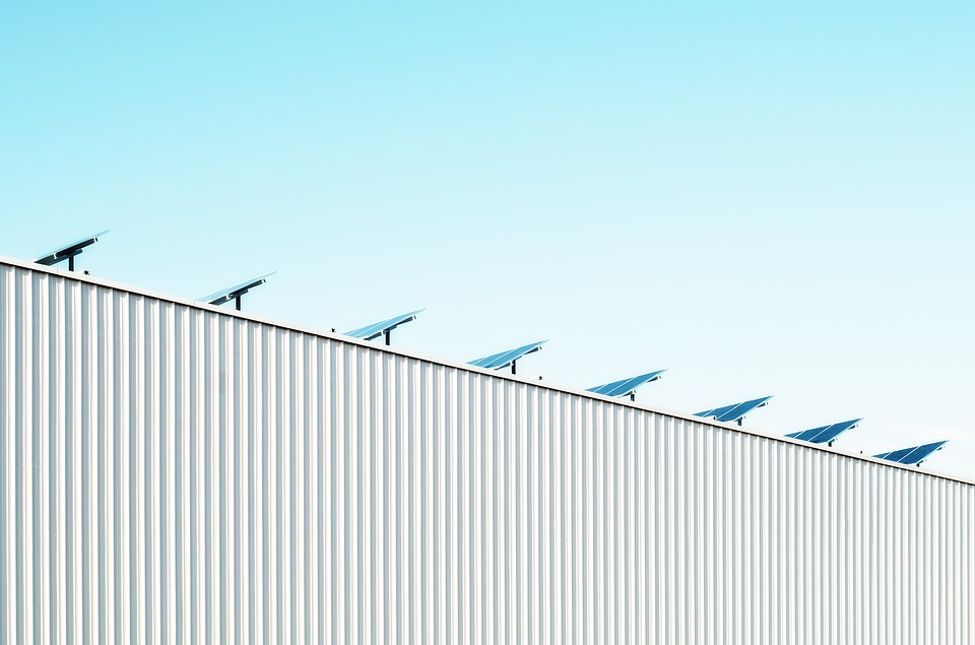

Green Manufacturing and the Use of renewable energy sources

The use of solar, wind, natural gas and hydroelectric power to power manufacturing facilities. Many businesses have invested in solar power facilities as well as wind farms to power their businesses.

Energy Efficiency

The use of energy efficient lighting such as the use of LED bulbs which use less power than incandescent and fluorescent lighting. Other companies even invest in architectural changes which maximizes the use of natural lighting during the day. These endeavors not only contribute to the environment but greatly minimize long term power costs.

Recycling

Manufacturing involves plenty of waste materials which green technology seeks to minimize. The food industry for example produce plenty of waste from plant and animal material. Companies that engage in green manufacturing can either use their by-products as energy resources or invest in technology that recycles them into other products thereby allowing them to diversify their offerings. Animal by-products can either become fertilizer or pet food. Wood chippings and sawdust can become charcoal bricks for furnaces and stoves.

Reduction of greenhouse gas emissions

In relation to the use of renewable energy, some companies now engage in the reduction of carbon emissions with the increased use of electric powered vehicles as well as vehicles that use biofuel. Carbon emissions from manufacturing facilities are reducing. This is due to new technologies capturing carbon as they’re emitted.

Reduction of the use of natural resources

Aside from reducing pollutants, it’s becoming increasingly important for manufacturing to use green technology in reducing their use of natural resources such as water and oil. Water is recycled through waste treatment or reused in other ways, while motors and vehicles continue to be improved for fuel efficiency. Manufacturing processes and equipment are optimized in order to use less fuel, time and materials. Thereby, resulting in significant returns.

Benefits of Using Green Technology to Manufacturing

- Reduces Environmental Impact – as discussed, the importance of engaging in green manufacturing is to lessen the impact on the environment through less solid waste, reduced greenhouse emissions and the reduction of the use of natural resources.

- Increases Revenue – adopting green technology can actually increase revenue by optimizing manufacturing efficiency and reducing the dependence on power consumption as well as maximizing the use of raw materials. Byproducts are recycled into other products or sold as additional revenue. While this is costly for existing companies, at least initially, the benefits are definitely attainable in the long run. Especially, when it comes to power consumption as well as public relations.

- Improves Image and Public Relations – manufacturing industries that actively pursue green manufacturing have much better public relations than those that don’t. Employees have a higher morale knowing that they work in a company that strives to reduce the global impact on the environment. Higher morale means wellness and greater efficiency.