The medical device industry is a complex ecosystem demanding precision, reliability, and rapid innovation. Traditional manufacturing methods, while effective, often struggle to keep pace with the escalating demands for advanced medical technologies.

Artificial intelligence (AI) emerges as a transformative force, offering unprecedented potential to streamline processes, enhance quality, and accelerate time-to-market. This article explores how AI is reshaping electronics manufacturing within the medical field.

FAQs:

Q: Can AI replace human engineers in electronics manufacturing?

A: Although AI excels at automating tasks, human ingenuity remains indispensable for complex problem-solving, creative thinking, and strategic decision-making.

Q: How can I ensure data privacy when using AI in medical device manufacturing?

A: Implementing robust data security measures, anonymizing patient data, and complying with relevant data protection regulations are crucial for safeguarding privacy.

Q: What is the return on investment (ROI) of implementing AI in electronics manufacturing?

A: The ROI can vary depending on factors such as the specific application, the scale of implementation, and the efficiency gains achieved.

Nevertheless, numerous organizations have realized substantial gains in efficiency, product quality, and financial performance.

Q: What are the future trends in AI for electronics manufacturing?

A: Future trends include the increasing use of advanced AI techniques like machine learning, deep learning, and natural language processing, as well as the integration of AI with other technologies such as the Internet of Things (IoT) and augmented reality.

Q: What are the specific AI algorithms most commonly used in electronics manufacturing for the medical field?

A: Core AI methodologies encompass machine learning, deep learning, computer vision, and natural language processing.

These algorithms are applied to tasks such as image analysis, predictive maintenance, and quality control.

Q: How can AI help address the challenge of cybersecurity in the medical device industry?

A: AI can autonomously identify abnormal network activity, uncover potential cyber threats, and initiate immediate countermeasures.

Additionally, AI can help develop more secure medical devices by identifying vulnerabilities in the design phase.

Q: How do human operators contribute to the effectiveness of AI systems in electronics production?

A: Human-in-the-loop systems involve human oversight and intervention in AI decision-making processes. This is crucial in the medical device industry to ensure safety, ethical considerations, and regulatory compliance.

Q: How can AI contribute to sustainable manufacturing practices in the medical device industry?

A: AI can optimize energy consumption, reduce waste, and improve resource utilization. It can also be employed to create sustainable materials and production methods.

Q: What moral and societal challenges arise from using AI in the creation and production of medical devices?

A: Ethical considerations include data privacy, bias in AI algorithms, and the potential for unintended consequences. It is essential to establish ethical guidelines and conduct rigorous testing to mitigate risks.

Q: How can small and medium-sized enterprises (SMEs) in the medical device industry benefit from AI?

A: AI-based solutions can be accessible and affordable for SMEs through cloud-based platforms and software-as-a-service (SaaS) models. These solutions can help SMEs improve efficiency, reduce costs, and compete with larger companies.

Q: What obstacles hinder the adoption of AI within the stringent framework of medical device manufacturing?

A: Challenges include data privacy, regulatory compliance, model validation, and ensuring the explainability of AI decisions. Collaboration between industry, regulators, and AI experts is crucial to address these challenges.

AI Engineering: A Catalyst for Transformation

AI engineering, the application of AI techniques to engineering problems, is proving invaluable in electronics manufacturing. AI technologies can optimize manufacturing processes across the board, from initial design concepts through prototyping, assembly, and quality assurance.

Design and Prototyping

Predictive Design: AI algorithms can analyze vast datasets of design parameters and performance metrics to predict optimal product configurations, reducing design iterations and accelerating time-to-market.

Material Selection: AI-powered systems can assist in selecting the most suitable materials for specific components, considering factors such as bio compatibility, durability, and cost-effectiveness.

Manufacturing Process Optimization

Predictive Maintenance: AI can analyze sensor data from equipment to predict potential failures, allowing for proactive maintenance and minimizing downtime.

Supply Chain Optimization: AI-driven algorithms can optimize inventory levels, procurement processes, and logistics, ensuring a steady supply of critical components.

Process Control: AI can monitor real-time process parameters and identify deviations from optimal conditions, enabling timely adjustments to maintain product quality.

Quality Assurance and Control

Defect Detection: AI-powered vision systems can inspect products for defects with exceptional accuracy, reducing the risk of faulty devices reaching the market.

Root Cause Analysis: AI can analyze quality data to identify underlying causes of defects, enabling targeted corrective actions.

Innovation and Product Development

Design Exploration: AI can generate novel design concepts, expanding the possibilities for innovative medical devices.

Product Personalization: AI can analyze patient data to create customized medical devices tailored to individual needs.

Potential Challenges and Considerations

While AI offers immense potential for transforming electronics manufacturing, several obstacles and factors must be carefully considered.

The accuracy and dependability of AI models hinge critically on the quality and quantity of data used in their development.

Model Development and Validation: Building and validating AI models requires specialized expertise and computational resources.

Adherence to regulatory standards: The medical device industry operates within a stringent regulatory framework. Ensuring that AI-driven systems comply with relevant standards is essential.

Ethical Considerations: AI systems must be developed and deployed ethically, considering issues such as data privacy, bias, and accountability.

The Future of AI in Medical Device Manufacturing

The integration of AI in electronics manufacturing for the medical field is still in its early stages.

Digital Twins: Creating virtual replicas of manufacturing processes can enable AI to simulate and optimize production scenarios before implementation.

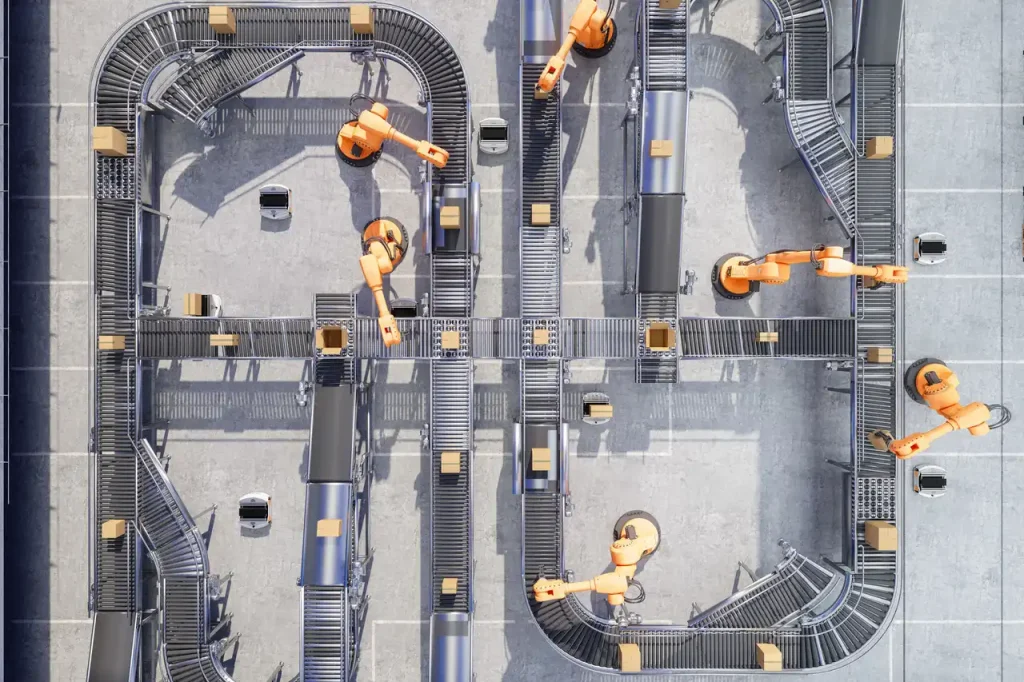

Autonomous Robotics: AI-powered robots could perform complex assembly tasks with greater precision and efficiency.

Advanced Analytics: AI can uncover deeper insights from manufacturing data, leading to further process improvements and product innovation.

Take Away

AI is poised to revolutionize electronics manufacturing in the medical field by:

Data is the new oil: High-quality data is the foundation for successful AI implementation. Medical device manufacturers must invest in data collection, cleaning, and management.

Collaboration is key: Successful AI integration requires collaboration between engineers, data scientists, domain experts, and regulatory affairs professionals.

Ethical AI is essential: Medical device manufacturers must prioritize ethical considerations, such as data privacy, bias mitigation, and transparency, when developing AI systems.

Ongoing learning and adaptation: The AI landscape is constantly evolving. Manufacturers must foster a culture of continuous learning and adaptation to stay competitive.

Return on investment (ROI) is crucial: Demonstrating the value of AI investments is essential for securing ongoing support and resources.

Talent acquisition and development: Building a skilled AI workforce is critical for driving innovation and achieving business goals.

Risk management: Identifying and mitigating potential risks associated with AI implementation is essential for ensuring business continuity.

Regulatory landscape: Staying informed about evolving regulations and standards is crucial for compliance and market access.

Patient-centric approach: AI should be used to improve patient outcomes and experiences.

Standardization: Developing industry standards for AI in medical device manufacturing can accelerate adoption and interoperability.

By addressing the challenges and embracing responsible AI development, manufacturers can unlock the full potential of this transformative technology.

Conclusion:

AI is undoubtedly transforming the landscape of electronics manufacturing in the medical industry. Through the adoption of AI tools,

AI is poised to become an indispensable catalyst for innovation and transformation within medical device production.