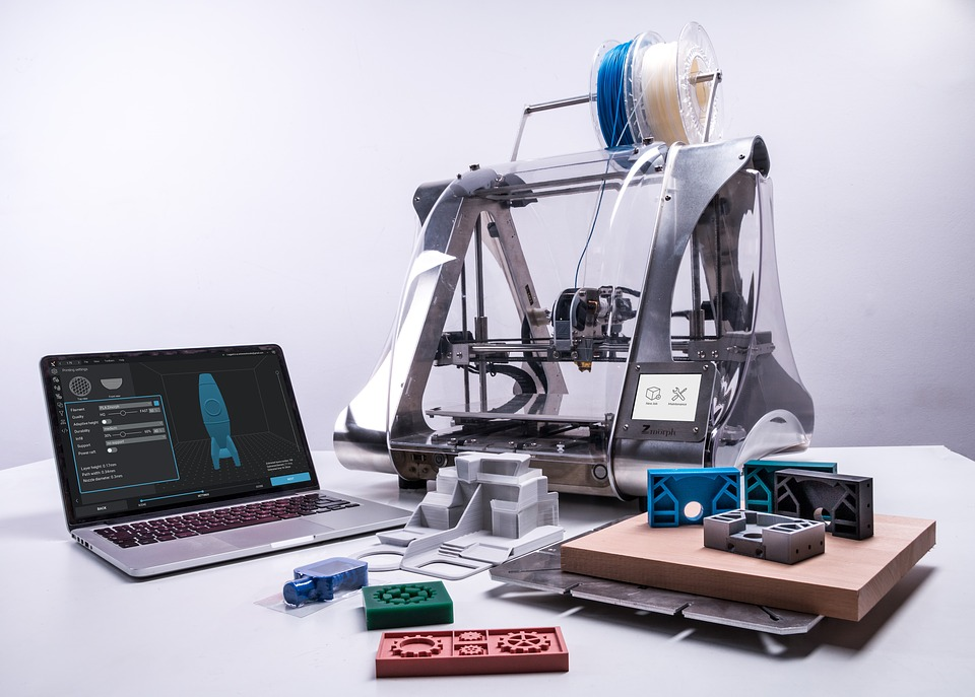

3D printing manufacturing processes are quickly gaining momentum in the manufacturing industry. Thanks to 3D printing, parts can be quickly designed, tested and manufactured several times faster than with conventional design for manufacturing methods (DFM). In fact, the integration of 3D printing in the design process greatly enhances DFM and companies that make use of 3D printing in their manufacturing process can get prototypes out much faster and end up with quality designs.

Manufacturing companies who have not yet engaged in integrating 3D printing in manufacturing should highly consider it. Thanks to 3D printing or additive manufacturing replaces the resource-intensive tooling and molding process when manufacturing a product and its components. Unlike before, and thanks to new 3D printing technologies, the limitation of what materials can be used are becoming less and less a factor during the design, manufacturing and testing of parts. The same thing is said with costs. This is because 3D printers are less and less costly as they become more ubiquitous in the market. 3D printing has already invaded the home market for enthusiasts and small businesses.

This process has greatly affected the general principles of design for manufacturing and actually blurs the highly dependent lines between them, that it’s easy for manufacturers to simplify or even ignore some of them. Yet the best products are those that always adhere to the following:

The Choice of Manufacturing Process

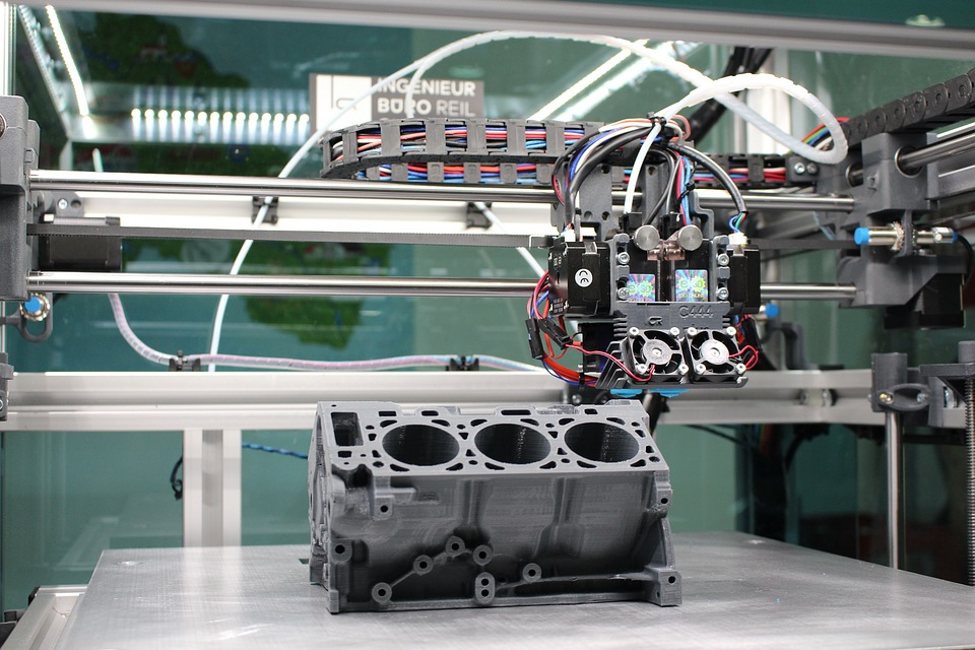

3D printing greatly simplifies the manufacturing process by reducing or removing the need for molding tooling. Some parts may require tooling and molding while others will no longer do so. Depending on the material, the steps of the manufacturing process become greatly reduced. Separate components are integrated and simplified. Those that used to be complex, are now made in ways without requiring any additional steps.

The Design Guidelines That Are Dependent on the Manufacturing Process

The nature of the product both influences their material and design. Home furniture, for instance, is either metallic or polymer-based. Both of which are used in the 3D printing processes. Once 3D printing manufacturing becomes a plausibility, the product’s design process and guidelines become easier. The design and process is even interchangeable when 3D printing is considered.

Choosing the Material Suitable for the Design and Manufacturing

The bottom line when choosing materials is cost effectivity. Will the material be durable enough yet inexpensive? Can the material withstand a certain manufacturing process? Will the material stand up to a product’s design? And will the material be inexpensive and durable enough to consider full-blown 3D printing manufacturing? With 3D printing however, any material chosen for final production can easily be determined once the design and prototypes are created. It goes without saying that rapid prototyping can be done through 3D printing. Component molds are produced faster and the best materials can be determined depending on the product design.

The All-important Testing Phase: Which Must Become Easier Depending on the Previous Three Design Principles.

The last stage of manufacturing design of course is product testing. Will the prototype be durable enough? Will the prototype be esthetically pleasing? Is the prototype simple enough or integrated enough to be cost-effective? 3D printing will be a great help in quickly producing a prototype.

In Conclusion

Therefore, when 3D printing is used in manufacturing, companies that use it gains the upper hand over those that don’t. Businesses that use it from the beginning can quickly grow and handle more clients if they’re subcontracting components for others.

However, it’s best to carefully consider the principles of design for manufacturing, with or without 3D printing in mind in order to churn out the best products. Manufacturer still have to contend with time, which influences all the design and manufacturing principles as well as cost. The proper integration of 3D printing in the design and process is therefore essential.