3D Printing and Electronics in Electronic Assembly

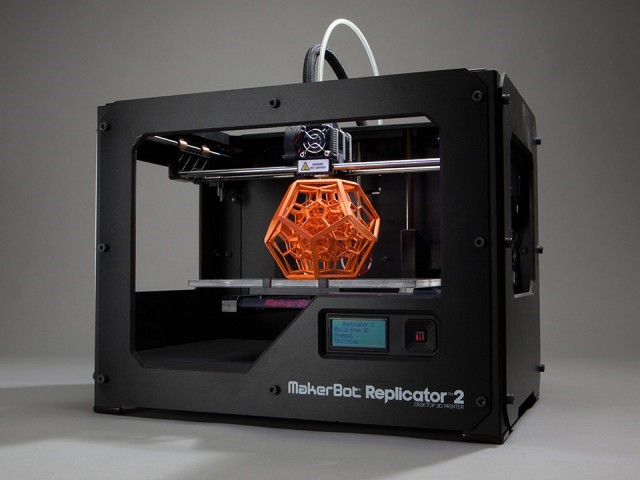

3D printing and electronics in electronics assembly is getting more and more prevalent because the two go really well together. 3D Printing technology has really advanced in a few short years. It allows more types of materials to be printed together. We are a society that creates whatever it wants and is dispensed from a machine. We can create simple models, toys, tools, and working mechanical machines and electronics from machines.

3D printing, in the realm of electronics assembly, makes it easier to create simple to complex electronic components and casings. These would otherwise take a long time to fabricate. Rapid prototyping is now faster than ever before thanks to 3D printing and electronics design. Once material and production costs lower, 3D printing will be used for manufacturing as well.

What does it take to for 3D printing and electronics assembly to work?

In the simplest sense, any 3D printer will work when producing components such as enclosures, frames and other non-conductive parts. As well as the PCBs themselves.

But it is possible to 3D print entire circuits as well as components such as transistors, switches, resistors and capacitors. This enables manufacturers to quickly create working circuits without the required chips and microcontrollers. This requires manufacturers to have specialized 3D printers that can print both conductive and non-conductive materials and everything in between. The materials required would be standard PLA, copper, aluminum, graphene. Or other conductive materials that can be dispensed by a 3D printer.

3D printing and electronics in electronic assembly is not necessarily new

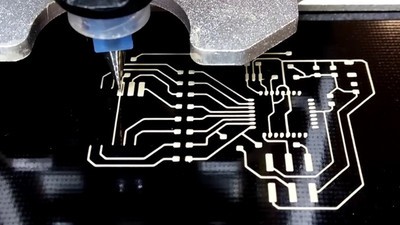

Initially, the name of 3D printing was “additive manufacturing”. Additive manufacturing basically means adding layer upon layer of material to create a finished product. This also doesn’t necessarily require a 3D printer. However, the process could go faster with one for the creation of the PCB. The process is then augmented by an inkjet-like printer that lays out the conductive material. This however, only applies to flat, horizontal circuits.

The actual 3D route utilizes 3D printers to print the PCB in the form and shape desired. This is done by using PLA while an additional extruder will be in charge of printing the conductive materials in the form of copper filaments or conductive gels. We are getting closer and closer to manufacturing entire electronic devices through 3D printing. But for now, 3D printing and electronics assembly mostly benefits large and small companies in their rapid prototyping of products.

3D printing and electronics assembly boost the speed in which new products are made from conceptualization to their release. You can see how fast major manufacturers are now releasing new models and products. It is common for it to take just around a couple months or more. It’s not just product releases that benefit from 3D printing technology. Soon it will satisfy manufacturers demand for anticipated products, once the technology of 3D printing further drop in production costs.